If the name wasn’t specific enough, the ‘RF100Ti Aircraft’ range of end mill tools from Guhring is a line of high performance end mills for cutting high tensile titanium alloys and special materials that are specified in the aerospace sector. The new milling series is ideal for slotting, ramping, plunging, trochoidal milling and orbital drilling, which makes this new innovation the tool of choice for the industry.

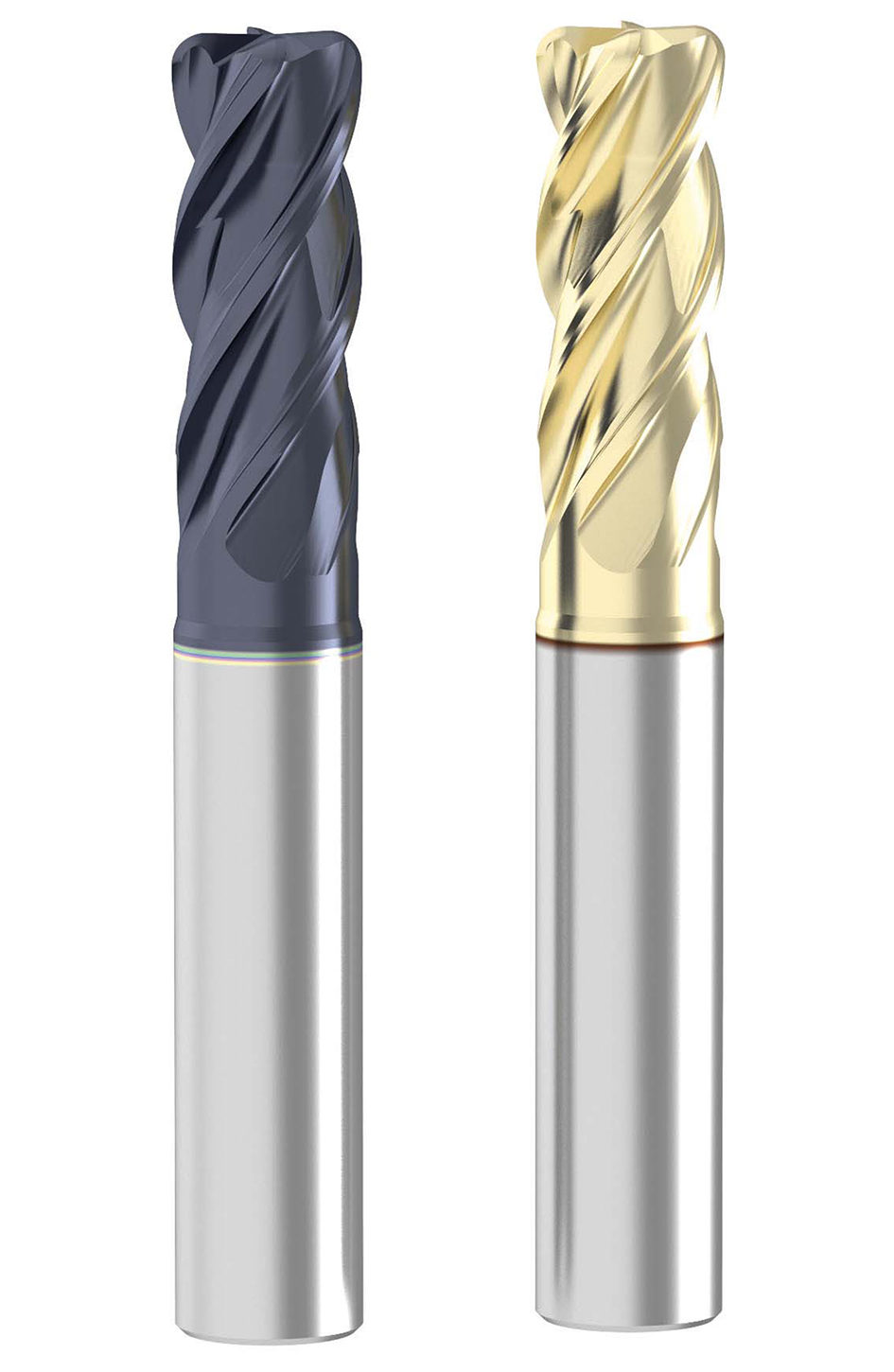

Specifically developed for the aerospace industry and the stainless steels and titanium alloys commonly machined, the new RF100 Ti Aircraft is a solid carbide range of tools with the choice of Guhring’s TiAlN Super-A coating or the new Zenit coating technology that glides through the material with its reduced adhesion characteristics. The four flute end mill series combines the choice of these two coatings with a geometry design that has been meticulously developed for extending tool life, material removal rates and overall efficiency whilst reducing cutting forces with its swarf evacuation characteristics.

To extend the tool life of the RF100 Ti Aircraft, the coating technology combines with an optimised corner radius that ranges from 0.5mm to 5mm. Available in diameters of 6, 8, 10, 12, 16, 20 and 25mm, the smaller tool diameters have the choice of six corner radii from 0.5 to 2mm whereas the 16, 20 and 25mm tools have a choice of eight corner radii from 0.5 to 5mm. The face of the end mill also has a particularly large chip pocket and web thinning that permit reliable plunging and orbital drilling whilst rapidly disposing swarf from the cutting area.

Tel: 0121 749 5544

Email: info@guhring.co.uk

Web: www.guhring.co.uk