Allied Automation (www.allied-auto.com) was established in Dublin in 1998. The main aspect of the company’s business is manufacturing bespoke, automated assembly machines used by many of the world’s leading medical, pharmaceutical, and life science companies. Allied Automation has its own modern high precision workshop and they say that pushing Alphacam’s Waveform strategy to the limit has reduced rough machining cycles by half.

Based at Finglas, close to Dublin International Airport, Allied Automation say their customers usually come to them with a project, and ask them to commission a machine to be built to automate part, or all of the production process. Since its foundation, the company has delivered over 2500 precision engineering projects to clients in Ireland, the UK, mainland Europe, USA and the Middle East.

Production Manager Owen Donnelly says they have recently completed a 15 month-long project for an assembly and test machine for feeding various sizes of catheters, coiling them on multiple mandrels, stripping them and loading them into sterile pouches, and sealing them at a rate of 30 PPM.

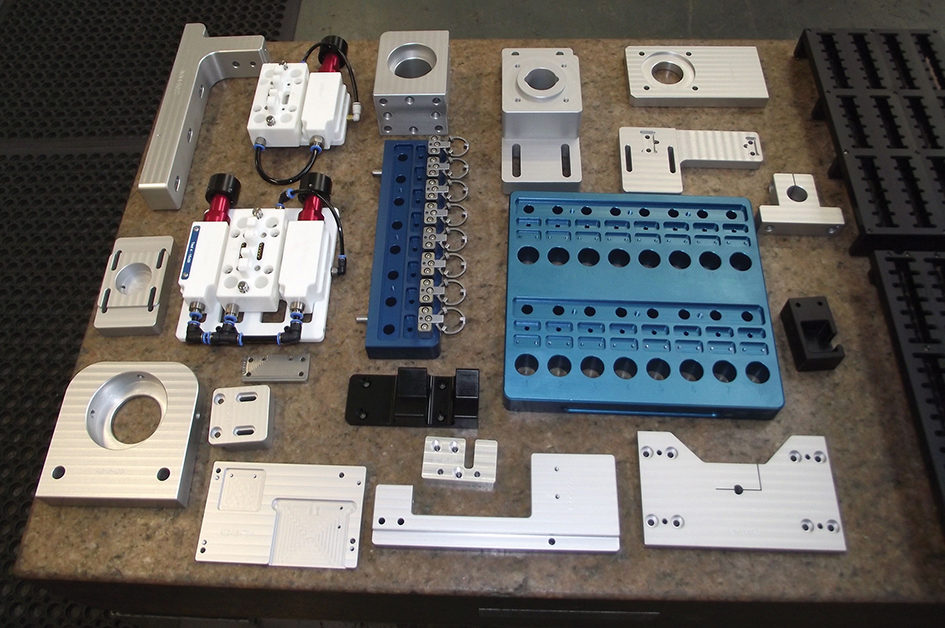

Each of Allied Automation’s machines can contain up to 5,000 components, and vary in size from small bench top assembly aids to 6 metre x 2.5 metre standalone machines. Owen Donnelly says the biggest revolution was the introduction of Alphacam’s Waveform Roughing technique, significantly reducing the overall machining time.

Toolmaker Daniel Monaghan says Alphacam makes his job much easier, reducing time, stress, and errors. “For example, if we were selecting a number of holes before, we would really have to focus on the various sizes resulting in potential errors. Now Alphacam groups them together, saving time and eliminating the risk of errors.”

Alphacam recently-introduced ribbon-style bar and fully customisable quick access radial interface, this originally took Daniel Monaghan and his colleagues well out of their comfort zone. “But once we got used to these new functions and realised the benefits, it has made our work easier and much more efficient.”

Email: luke.paines@verosoftware.com