Dynashape, the experienced sawblade servicing and manufacturing specialist, has secured a new 12-month contract with Britain’s largest specialist cold roll-forming company, voestalpine Metsec plc. The contract is for the supply of TIALN-coated SHSS (Super High Speed Steel) and TCT (Tungsten Carbide Tipped) sawblades, as well as for sawblade remanufacturing.

“This will be the second year that we have provided sawblade services for Metsec,” comments Dynashape’s Managing Director, Chris Parkes, “and I am absolutely delighted that the team at Metsec has chosen to appoint us again. When we first won the business in 2015, we demonstrated how our sawblades were capable of delivering in the region of 3,000 cuts per blade. That’s around 900 more cuts per blade than Metsec was achieving using a competitor’s products. More importantly, it underlines the true cost effectiveness of the improved sawblade technology that is employed by Dynashape.”

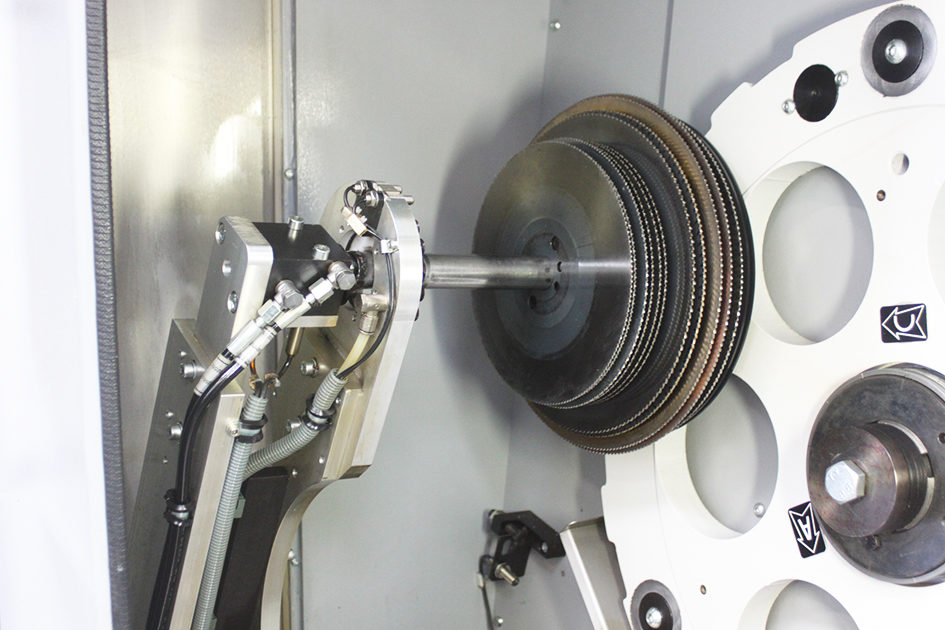

Providing Metsec with sawblades that have a much longer life, however, really is only part of the story. Dynashape’s considerable investment in the latest CNC sawblade manufacturing technologies – the same machinery that is used by leading sawblade producers globally – means it is also able to remanufacture Metsec’s blunt blades to ‘as new’ standards.

Dynashape is part of the Addison Group, a UK-based organisation that has been at the forefront of metal sawing technology since 1956.

Tel: 01384264950

Email: news@addisonsaws.co.uk

www.addisonsaws.co.uk