The production of high-quality aluminium extrusion tools is an art unto itself. Only few companies match the precision and quality with which the Italian Alumat-Almax-Matrex masters this process. Through the introduction of Blum Novotest laser measurement and touch probes in its machining centres, the manufacturing time can be reduced significantly and the accuracy of the products has significantly improved.

Alumat was founded in Ciserano near Bergamo in Italy in 1994. It employs about fifty staff in the design and manufacture of steel dies for aluminium extrusion. The continuous growth led to an expansion of the business resulting in increased production capacity and a tripling of sales within 4 years.

“The special thing about our activities is the fact that our tools are essentially individual items created specifically for our customers. Not only do we supply individual dies, but also the entire planning and validation of the product,” says Emanuele Astolfi, Manager at Alumat.

From planning to completion, a tool will undergo up to 15 production steps that we currently realise in about six days This took us as many as 15 days some ten years ago.”

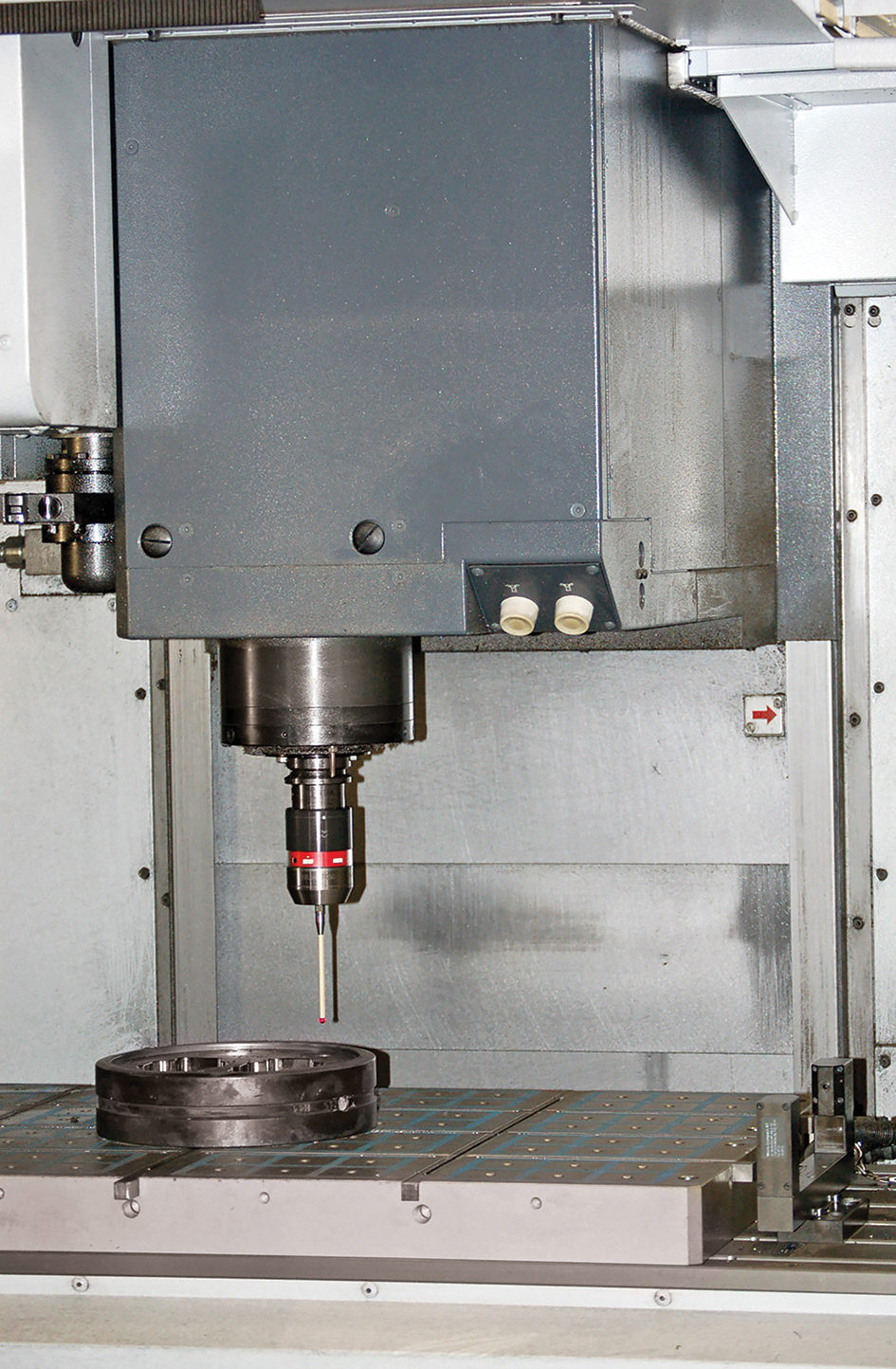

This improvement required the deliberate use of machining centres and the attempt to optimise all processes. The company looked for systems that would avoid any down time and facilitate machine-integrated quality control. In addition, the systems had to allow direct access during each production phase, in order to correct any deviations immediately. Then, six years ago, Alumat decided to confide in the technology and professionalism of Blum Novotest. Since then, the machining centres have been equipped with BLUM systems that both check workpiece position, dimensions and also monitor the tools. These instruments soon facilitated the achievement of the desired quality level while delivering reduced lead-times.

Today all operations of the company use the Blum LaserControl system for contactless measuring and monitoring of the cutting tools. In many machine tools, the Z-MT Type tool setting probes ensure the high level of production quality.

“The Blum-Novotest products have definitely proven themselves in recent years. This is why we decided to gradually replace the systems from other manufactures. Our Blum measuring technology facilitates precise, reliable and competitive production. The customer service provided to us by the Italian branch of the German metrology specialist also played a decisive part. The reaction time of the experts employed at Blum is extremely short and very supportive,” concludes Mr Astolfi.

Tel: 01283 569691

Email: david@blum-novotest.co.uk

www.blum-novotest.com