When G R Contracts, a leading supplier of structural steelwork for the construction industry, were looking to invest in new steel processing machinery to increase productivity and reduce production costs, they never envisaged that it would have such a radical impact on their business.

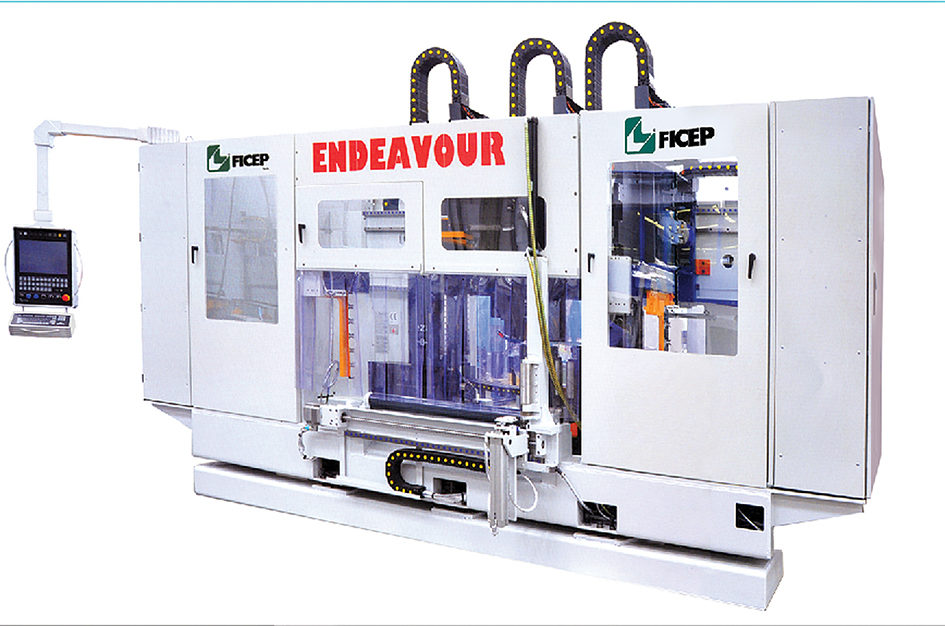

After investing time and effort into evaluating machines from several manufacturers they choose the Endeavour – FICEP’s fastest ever automatic CNC line for drilling, milling and marking for beams channels and flats.

Not only have G R Contracts seen substantial increases productivity, the scribing facility on the machine has substantially reduced the the fit up time for the fabricators. This has resulted in the fabricators finding that time has reduced significantly with the new Endeavour because they usually had to mark out and mag drill then fabricate the steel. As now they just have to fabricate the steel, the company decided to run the machine on 2 shifts which meant they doubled output with the same number of fabricators.

Robert Savage, Director of G R Contracts, said: “We have now seen benefits of between 20-30% more pieces produced on one shift compared to the previous methods which using a saw on two shifts. When we have moved to 2 shifts on the Endeavour we are seeing a further 20-30% increase which equates to an overall 50-60% increase in pieces / productivity from the new machine. This is a result that has far out exceeded our expectations.

Tel: 1924 223530

Email: info@ficep.co.uk

www.ficep.co.uk