Harlow College’s Advanced Manufacturing and Engineering Centre (HAMEC), which is to open in early 2017, is the culmination of intensive research and collaboration between public bodies, local industry and high technology suppliers. It will offer vocational training for apprenticeships and degree apprenticeships, providing a pool of talent ready for the challenge of modern manufacturing.

Will Allanson, Executive Director, Business Development for Harlow College says, “Harlow is central within the London, Stansted, Cambridge corridor, a STEM and high technology corridor and we recognised that there was an opportunity to support innovative businesses in the area. Essex County Council carried out a feasibility survey and the college in partnership with the SEMTA (the Sector Skills Council for Engineering and Manufacturing) and others carried out further surveys to find out in detail what local employers were saying.”

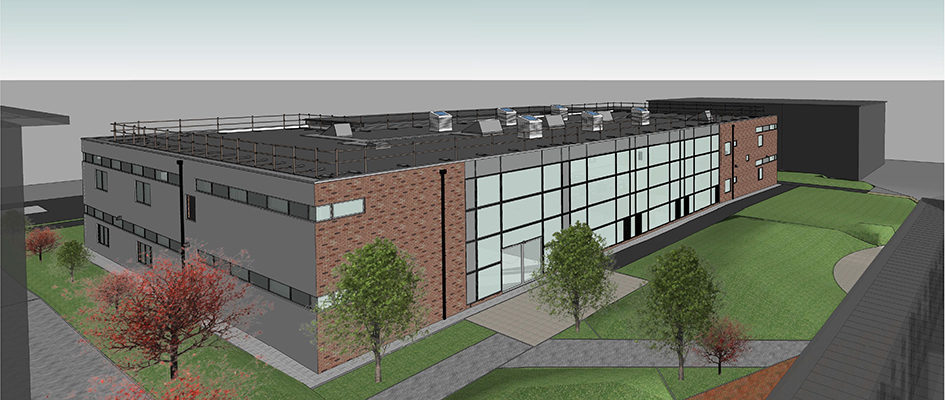

Harlow College: Rendered image of the HAMEC building

The result was a clear need for training in 5-axis simultaneous CNC machining, laser measurement and lean manufacturing. Working with an advisory board of 40 employers Harlow College have developed a curriculum aimed at meeting the skills needs of employers. Key to making this successful was the need to procure specified new equipment. In going to procurement we set three main criteria which were the ability of the supplier to offer machines which met the needs of the project, value for money and the ability to develop a deeper relationship through an ongoing partnership. Will Allanson says, “DMG MORI’s ability to meet all our requirements and especially its technical partnership expertise made it the obvious choice for us.”

Harlow College invested in a DMU 50 with Heidenhain control, an NLX 1500 SY with Mitsubishi control and CELOS®, an ecoMill 600V with Siemens control, an ecoTurn 450 with Mitsubishi control and a UNO 20|40 tool presetter. DMG MORI also supplied a full suite of simulators for Heidenhain, Siemens and DMG MORI APL, which will go in the new CADCAM and simulation suite, along with SolidWorks and SolidCAM. It also facilitated the supply of a CMM from Hexagon Manufacturing Intelligence.

The new 2000 m2 building has two floors with a central machine shop and offers a flexible manufacturing space for students and local employers. The HAMEC will focus on three areas – advanced manufacturing engineering, operational and plant maintenance engineering and aerospace maintenance. The aim is to train local companies and retrain staff with the high technology equipment and offer facilities for companies to carry out feasibility studies and development for new products, explore lean processes and offer emergency extra manufacturing capacity. Will Allanson says, “There will be considerable value for the HAMEC, students and local companies in working on real projects and we anticipate that the interchange will rapidly build the skills of everyone involved and ensure that the centre covers its costs.”

The technical partnership with DMG MORI will offer an opportunity for HAMEC students to benefit from the company’s relationship with other centres in the UK such as the MTC in Coventry, DMG MORI’s own technical centres in the UK and Europe and from visits to prestigious customers such as Red Bull. The company will also offer ongoing support and training and plans to organise local events, bringing in its technology partners such as Hexagon Manufacturing Intelligence and Jemtech, tapping into their customer bases, to provide educational and networking opportunities for local businesses. DMG MORI also wants to use the HAMEC as a showroom for its products in the South of England and, where appropriate, loan additional machinery to the centre.

Steve Finn, Managing Director of DMG MORI UK says, “Vocational training in engineering is something that we are very keen to support, so working with the HAMEC to make it a success is a high priority. DMG MORI has been supporting the WorldSkills and WorldSkills UK competitions for several years and Harlow College is planning to develop some of its students for the competition. We will be offering them maximum support as part of our technical partnership.”

Will Allanson says, “Employers are looking for people that are work ready. In line with employer demand, we have taken a 36 week programme and condensed it down to 26 weeks, where students work a 5 day week starting at 8.45 am. It is an intensive practically based programme, also concentrating on English, maths and employability skills, enabling local companies to take students for 3-5 weeks after just one term of training to assess their suitability. Already 11 out of the 13 people who have been through this process have started an apprenticeship. Our success is measured in outcomes for our students. We record destination data for the young people 6 – 18 months after college and we are confident that the HAMEC, its technical partnerships and links with local industry will make a considerable contribution to their long term success.”