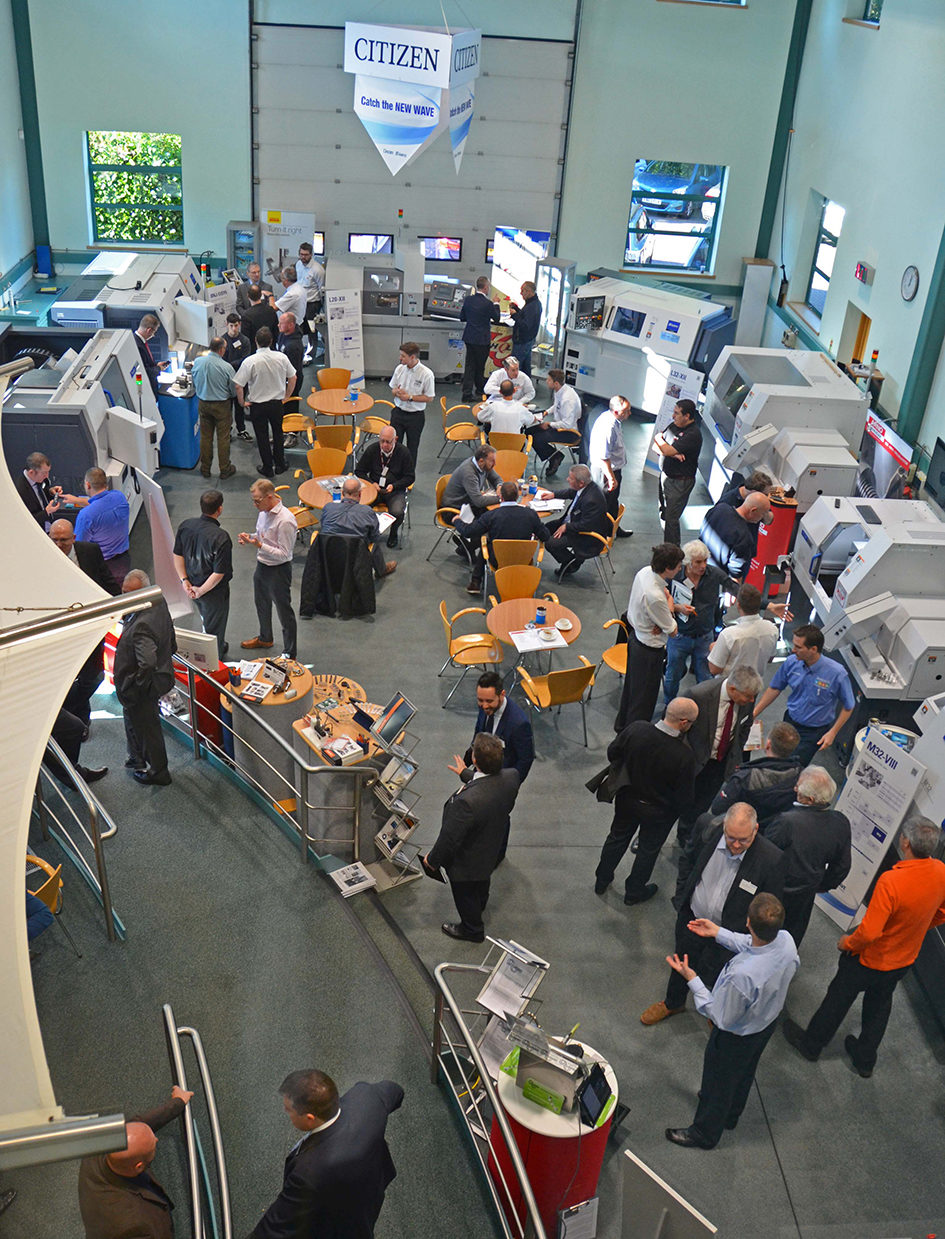

Citizen Machinery’s launch of its Low Frequency Vibration (LFV) cutting technology plus integrated laser cutting on two of its Citizen CNC sliding head turn-mill centres drew almost 300 potential customers and visitors to its three-day Open House where 18 machines from the Citizen and Miyano fixed head ranges were being demonstrated.

As a result of the event, over £2 million of machine tool future investment orders were placed by visitors to the Bushey headquarters with some travelling from as far away as Scotland and Ireland and internationally from Denmark, Sweden, Germany and Portugal.

Said Sales Director Darren Wilkins: “We have often demonstrated how new machine tool technology reduces non-cutting time. However, this was the first time we have radically broken new ground in changing the machining process and the cutting of material. It has certainly created interest with us taking orders for machines with integrated LFV technology due for delivery in January and considerable longer term pre-order intent.”

Visitors were also able to view live demonstrations on some of their own components being manufactured on the latest Cincom L20-VIII using ‘programmable’ LFV technology to control chip removal on materials that are normally challenging to manage even with high pressure coolant. Said Mr Wilkins: “Most visitors were able to appreciate the opportunity to remove or reduce the need for high pressure coolant as well as the potential advantage to increase productivity and reduce the cost of expensive consumable tooling.”

Added Mr Wilkins: “Many sliding head users immediately recognised the advantage of LFV in greatly improving the removal of swarf from the machining area and its help to reduce downtime as a result of damaged or worn tooling. As the vast majority of our customers run Citizen machines unattended they therefore welcomed the opportunity to extend their production capability and were enthusiastic over the ability to switch, as required, to suit the application between the ‘programmable’ chip control development and a conventional non-LFV machine.”

Luke Dealhoy of Gedore Torque drew the top prize of an Orange mountain bike fitted with high specification Hope equipment produced on both Citizen and Miyano machines installed in its factory in Bartnoldswick, Lancs. To qualify for the draw Mr Dealhoy remembered to bring along his token from his visit in April to the Citizen stand during MACH 2016 at the NEC. Meanwhile, Simon Lilley of S. Lilley & Son is now the proud owner of a new Citizen Eco Drive watch from the visitors card draw at the event.

Citizen Machinery UK Limited, 1 Park Avenue, Bushey, Watford, WD23 2DA

Tel: 01923 691500

www.citizenmachinery.co.uk

Contact: Mr Geoff Bryant, Managing Director

gbryant@citizenmachinery.co.uk