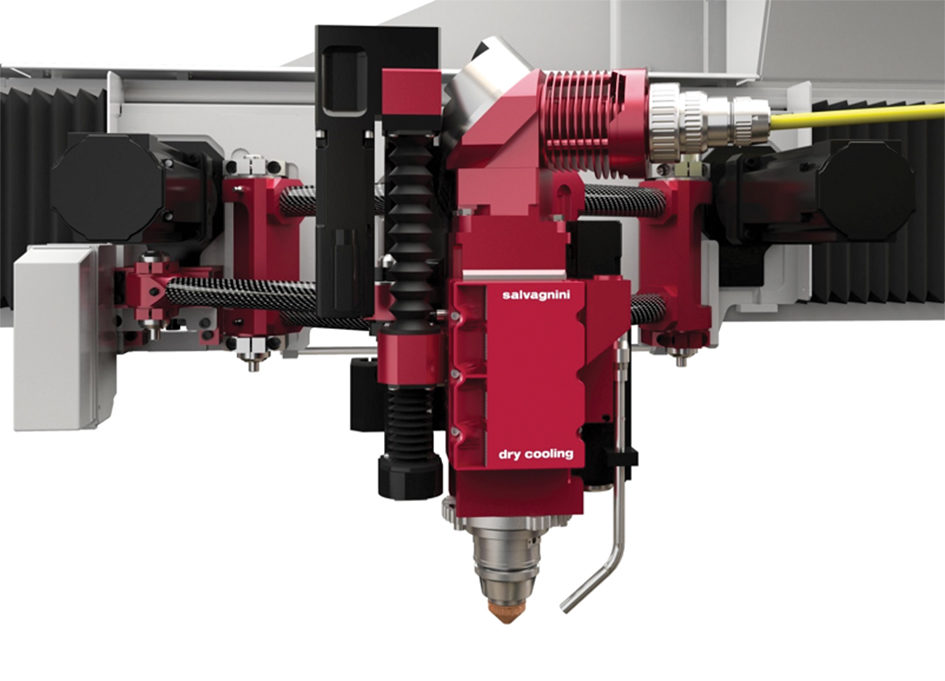

Salvagnini are renowned for flexible automation and innovation in sheet metal. The latest development from the company who were the first to introduced Fiber Lasers to the market place back in 2008, is a patented lens cooling system on their flagship L5 model Laser. Its proprietary cutting head is enriched by the new “Dry Cooling” feature, an innovative system that cools the optics without gas. This active refrigeration system monitors and controls the temperature of the focusing lens, extracting, only when necessary, the heat required to maintain a stable temperature.

Dry cooling actually allows a further reduction of the operating costs of fiber laser systems: it reduces the consumption of nitrogen (the cost of which, depending on the country of installation, can be significant) and the cost of consumables, thanks to the increased service life of the optics.

In addition, this cost reduction is accompanied by an improvement in cutting reliability.

Tel: 01989 767032

Email: steve.williams@salvagninigroup.com

www.salvagninigroup.com