Now available in the UK and Ireland from official importer, sales distributor and sales agent, TDT Technology, is the Feeler range of FTC turning centres and slant bed CNC turning centres. Aimed at machine shops tasked with heavy-duty machining operations, these advanced machines offer an extremely competitive cost-to-performance ratio.

The Feeler FTC range comprises three models, the FTC-10, FTC-20 and FTC-30. Between them, the machines cover a swing-over-bed of 520 to 600mm diameter, a standard turning diameter of 180 to 310mm, a maximum turning diameter of 240 to 450mm, and a maximum turning length of 255 to 621mm, making them ideal for most heavy-duty turning applications across industry.

All three FTC turning centres feature a spindle equipped with high-precision, dual-direction, angular-contact thrust ball bearings to meet the needs of demanding cutting operations. A special heat-dissipation headstock design eliminates elevated temperatures from the spindle bearings, thus prolonging life and promoting reliability.

Featuring a host of optional automation options, such as tool setting and part measuring, as well as automated loading and unloading of parts, the Feeler FTC series is designed for unmanned operations around the clock. Maximising productivity and profits are the ultimate aims.

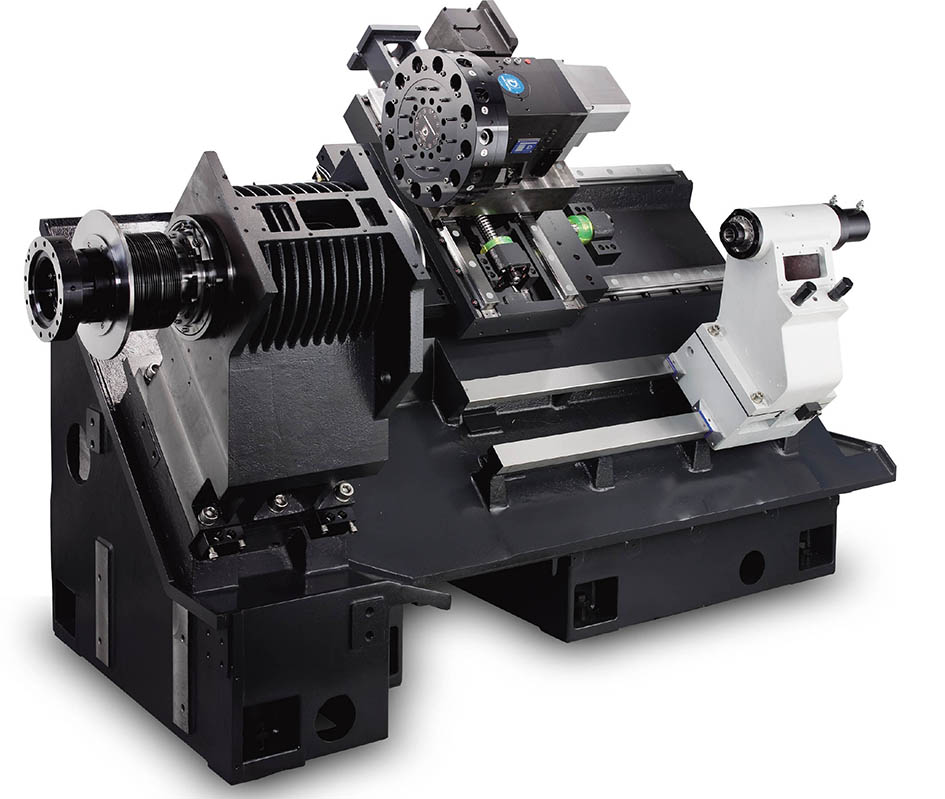

FTC-450MC Unguarded

Machines in the Feeler FTC series of slant bed CNC turning centres are designed for rigidity, efficiency and versatility. Kicking off the range is the FTC-300, which features a 6000 rpm spindle, 6” chuck and 52mm diameter bar capacity. Moving up, the FTC-350, 350L, 350XL, 350LY (Y axis) and 350SLY (twin spindle) offer a 4500 rpm spindle, 8” chuck and 52mm diameter bar capacity (66mm option). All feature a 30° slant bed that provides operational safety, accuracy and easy chip control.

For an even more robust structure, the FTC-450 and 450MC (C axis and driven tools) provide a 45° slant bed, a maximum turning diameter of 450mm and a maximum turning length of 650mm.

Finally, for the ultimate power and rigidity, the FTC-640 and 640L again feature a 45° slant bed, which is matched with a 15” hydraulic chuck, 117.5mm bar capacity, 22/26kW spindle motor and A2-11 heavy-duty spindle.

Among the principal features of these machines are the use of oversized linear motion guideways on the X and Z axes. Linear guideways provide a reduced co-efficient of friction along with increased speeds and feeds. As a result, Feeler FTC series turning machines offer a rapid feed rate of 30m/min.

All FTC-series slant beds are manufactured from single-piece Meehanite cast iron for outstanding material stability and long-term deformation-free performance. Furthermore, the entire machine construction has been subjected to ANSYS and NASTRAN FEA (finite element analysis) to help optimise rigidity, ultimately making light work of heavy-duty turning.