Solid steel chains for horizontal drilling machines: harsh demands, flexible solution

Robust steel cable carriers from KABELSCHLEPP Metool have proven successful, as in the horizontal drilling machines from Prime Drilling GmbH, which allow trenchless laying of pipelines up to 60″ deep and over a distance of up to 3,000 meters. To allow Prime Drilling to work as flexibly as possible, KABELSCHLEPP Metool implemented the drag chains as a customized standard solution with short delivery times.

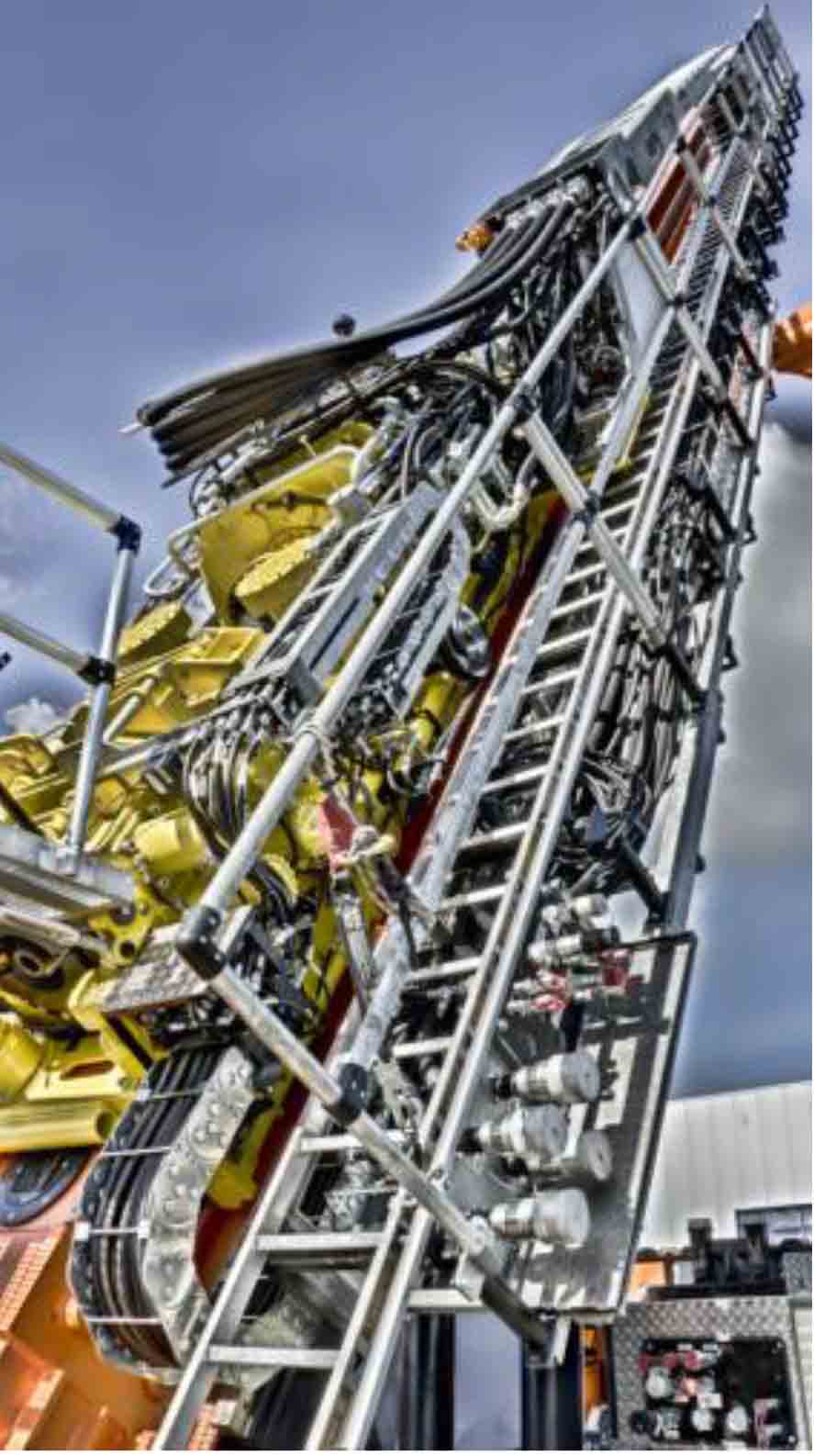

The drag chains are attached to the carriage masts at the sides of the drilling systems, guiding and protecting the hydraulic hoses. In consultation with KABELSCHLEPP Metool, Prime Drilling selected the S series cable carriers for this purpose – these extremely robust and heat-resistant steel solutions are designed for heavy mechanical loads and harsh production environments. An ideal solution for the drilling systems from Prime Drilling – particularly as TSUBAKI KABELSCHLEPP still makes further individual modifications to the steel cable carriers. “Installation space is limited with deep-drilling devices. The drag chain therefore has to use a highly compact design to guide a huge number of large and heavy hoses,” explains Luis Miguel Berjano, design engineer in charge of drag chains at TSUBAKI KABELSCHLEPP. The modifications are therefore primarily based on optimum use of available space and a particularly rigid cable carrier design, also in the interior – specifically in the area of the dividers, which are made of steel, just as the actual chain links. KABELSCHLEPP Metool also designed fitted end connectors which compensate the additional height of the mounting frame stay. Not lastly, the experts also adapted the pretension of the cable carrier to enable an extensive unsupported length of the drag chain despite the high weight of the hoses.

Overall, this is an individual custom solution which normally involves extended delivery times. To avoid this, KABELSCHLEPP Metool agreed with Prime Drilling to always keep a certain number of the required special parts in stock. But there is more: In order for the customer to always stay flexible in the development of drilling machines, KABELSCHLEPP Metool offers the drag chains as a modular system. Prime Drilling achieved this by defining several basic machines for which suitable basic cable carriers were then developed. “This enables us, for example, to modify the content and length of the drag chain,” confirms Lothar Zeppenfeld. The design manager at Prime Drilling is very satisfied with the solution that was developed jointly by the two companies.