With an increasing volume of work MCC Industries Ltd., along with its sister company Automotive Accessories Ltd., recognised the need for additional turning and milling capacity. With space being limited at their Southampton premises, Managing Director Mark Cox decided mill-turn was the obvious answer. In selecting the right machine, he laid out some key requirements: the machine had to be operator friendly, easy to set up and, robust enough to maximise the capabilities of the latest cutting tool technology on a range of materials including stainless steel. After meeting all of Mark Cox’s criteria, the machine chosen to see MCC Industries enter the mill-turn sector, was the XYZ Compact Turn 65 LTY.

MCC Industries and Automotive Accessories operate from the same facility, with MCC specialising in general sub-contract CNC machining, including finishing and assembly operations, for a diverse customer base, with batch sizes ranging from one-offs to 1000 off, or more. Meanwhile, Automotive Accessories is one of just two companies worldwide manufacturing H-Point Manikins and Head Restraint Measuring Devices (HRMD) for the Automotive Industry. These products are used in the design and testing of automotive interiors, particularly for seating systems and whiplash testing approvals to Euro NCAP standards. Automotive Accessories Manikins and HRMD units are purchased by car manufacturers, automotive design houses as well as all the Euro NCAP testing facilities throughout the world.

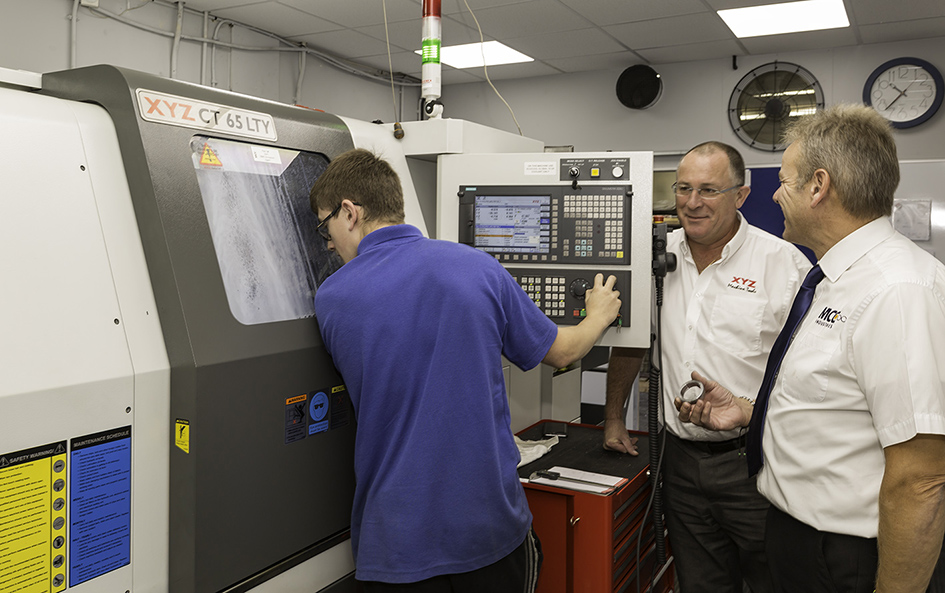

The ease of use of the XYZ Compact Turn 65 LTY and its Siemens 828D ShopTurn Control overcame one of Mark Cox’s main issues, the availability of skilled people. “Skilled people can command too higher salary and often have some poor pre-conceived ideas on the best way to do things. This isn’t always the best route for companies like ours, so we invest heavily in training people and currently run an apprenticeship scheme. To bridge any skills shortage, we need machines that are straightforward to setup, without compromising the capability to do exactly what we need,” says Mark Cox. The XYZ Compact Turn 65 LTY came out on top for a number of reasons; it has a large 65mm through spindle capacity coupled with live tooling, and 70mm Y-axis travel. These features will enable production cycles to be maximised, enabling complex components to be manufactured on one machine in a single operation. Previously we would have to turn and then mill the component on separate machines, whereas now they are coming off complete in a single operation, freeing up milling capacities on other machines.”

From a control point of view the Siemens 828D Shopturn control ticked many boxes for Mark Cox: “It is extremely user friendly and, importantly, for machines supplied by XYZ Machine Tools, all of the control options are activated, which would have been charged as optional extras from other machine suppliers, adding several thousands to the purchase price. In my opinion the Compact Turn and Siemens control are perfect partners and we make full use of the Siemens JobShop Concept which, with its on-screen prompts, make programming a straightforward process and simple to understand. Something that is further enhanced by the line trace graphics and full 3D graphics, which are available for final verification of toolpaths prior to machining.”

A further advantage was that MCC Industries was already familiar with the Siemens control as it has an XYZ 1020 VMC with the ShopMill version of the control, as well as an XYZ ProTURN SLX 425 lathe and an XYZ SMX 3500 bed mill, both fitted with the ProtoTRAK control system. With these machines, MCC Industries had already experienced the high level of customer service, technical support, training and the customer focused approach of XYZ Machine Tools. These factors certainly influenced its decision to purchase the Compact Turn 65 LTY. “We were more than happy with the service we had received from XYZ and this was reaffirmed when we placed the order. The installation of the mill-turn centre was going to be a tight fit, as we needed to remove an inside wall, as well as relocate our stores and inspection departments. In spite of this everything ran smoothly and the machine was quickly in full production,” confirms Mark Cox.

The XYZ Compact Turn 65 LTY comes as standard with a 23HP/17kW/4500 revs/min spindle, a 12 position VDI turret with all positions allowing live tooling with spindle speeds up to 4500 revs/min, the rigid, box slideway, construction of the machine creates an ideal machining platform, maximising metal removal rates and performance, enhanced by 20 m/min maximum feedrates in all axes. Over and above the standard equipment, Mark Cox specified the optional LNS Alpha 65S Servo Barfeed unit, as well as a Hainbuch 65 mm capacity collet chuck. These options create what Mark Cox describes as a machining centre with a bar feeder.

While the XYZ Compact Turn 65 LTY is a recent arrival at MCC Industries, it is already having a positive impact. One particular complex component that previously required multiple set-ups had long been a problem job, with unacceptably high reject rates. Using the Compact Turn this is now machined complete in a single operation and MCC Industries is achieving a 100 per cent acceptance on the parts. “We now find that we can hold size and tolerance all day long without any variance, other than tool wear. This gives us the confidence that we can deliver on our promises to customers. Our philosophy is to do the right thing in terms of customer service, on-time delivery and quality. The XYZ Compact Turn 65 LTY is enhancing that. Not only have we gained additional capacity and capabilities from the mill-turn, we have opened up new opportunities to bring in more work to the business and coupled with other investments we have made in our inspection department and the purchase of a new CMM. XYZ is helping to progress the business by increasing efficiency and maximising our available man hours,” says Mark Cox.

MCC Industries is a fairly typical XYZ Machine Tools customer, one that is growing through investment in machining technology, with the support of XYZ’s technical support and training. “While we are installing over 1000 machines each year, we have never lost focus of what has helped us to succeed, that is to support our customers with the service and training they need to operate efficiently,” says XYZ Managing Director, Nigel Atherton. “The result is that we have many returning customers, such as MCC Industries that have grown alongside XYZ into successful businesses. We see it as a common-sense approach to customer service, and it is one that pays dividends for all concerned.”