AddUp and ESI Group intensify collaboration

Industrial additive manufacturing (AM) solutions provider AddUp and virtual prototyping pioneer ESI Group, both of which are French owned, are intensifying their collaboration with the creation of Distortion Simulation AddOn, an ergonomic simulation module they jointly designed specifically for metal 3D printing. The AM equipment manufacturer, AddUp, a Michelin and Fives joint venture company, is represented in the UK, Ireland and the Middle East by sole agent, Kingsbury.

Available from the spring of 2019, the Distortion Simulation AddOn module will enhance the range of functionalities of AddUp Manager, which is design and management software for the definition and production tracking of parts during the AM process. At a time when the industrialisation of AM has become a reality, simulation based on material physics, ensuring an in-depth understanding of material processes and behaviour, is a key component to improving competitiveness.

Manufacturers must be able to maximise production time, to which end optimisation of AM process parameters is crucial and a driver of differentiation. Traditionally, production validation has primarily meant producing parts and then assessing their conformity, requiring multiple feedback loops and creating discontinuity over the digital chain.

By integrating simulation directly in the preparatory stages of AM, Distortion Simulation AddOn brings continuity to the production process. The intuitive and stable AddUp Manager user interface, which takes care of slicing and generating laser scan paths and defining laser melting patterns, offers the ideal working environment for establishing simulation parameters, particularly for staff who are not experts in the field.

Vincent Ferreiro, CEO, AddUp explained, “With this simulation technology we can help our customers improve their operational efficiencies and responsiveness by significantly increasing the number of first-time-right parts.

“Thanks to its accessibility and requiring only a very short learning curve, Distortion Simulation AddOn will appeal to a wide range of users. This tool will help them maximise the potential of our FormUp machines.”

The process is based on a succession of simple, guided steps and the level of detail is configurable according to a customer’s needs, from optimising industrial production to verifying small series.

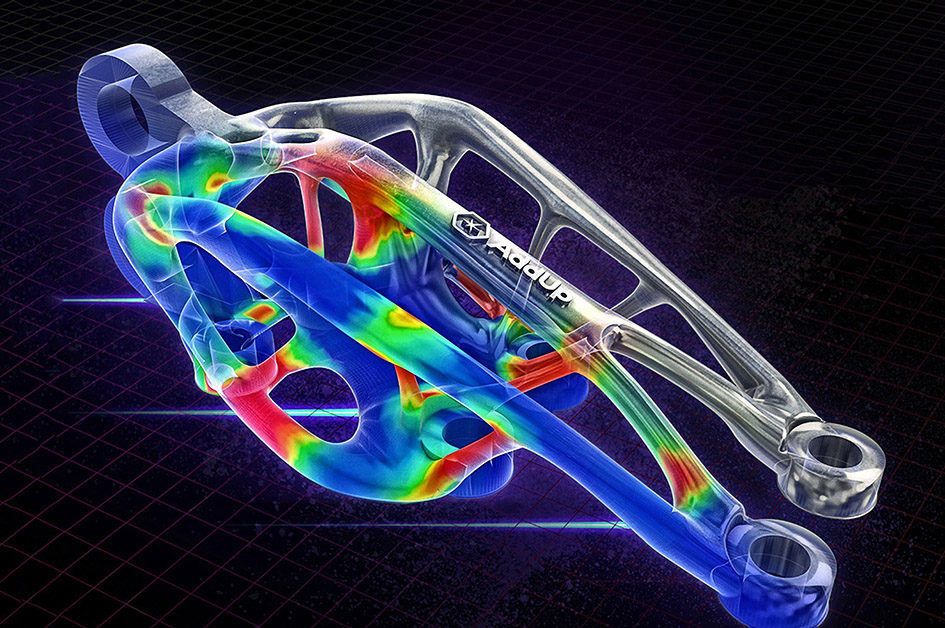

Simulation results allow physical characteristics of parts, displacements, strains and residual stresses to be correlated with the feasibility criteria calculated upstream of production. It allows risks of production downtimes due to collisions of the roller or scraper to be anticipated. At the end of the process, a modified geometry is generated. Based on predicted deformations due to the process and exportable in STL format, it helps to ensure geometrically compliant production.

Vincent Chaillou, COO, ESI Group commented, “The complementary nature of our teams and our fields of expertise, backed up by our collaboration in the SOFIA* project, has enabled us to develop an industrial solution that delivers performance, predictability and competitiveness while continuing to implement innovative production methods such as additive manufacturing.”

Based on complementary expertise, AddUp and ESI Group have firmly established their cooperation, sharing know-how and building their respective competitive strengths for the future. AddUp, with its highly open and flexible production systems, is further improving its mastery of industrial processes and the power of its software packages. ESI Group, with its background in material physics, reinforces simulation of machine behaviour in metal additive manufacturing at the highest level.

* SOFIA – Solution pour la Fabrication Industrielle Additive métallique (Industrial Metal Additive Manufacturing Solution).

For further infomation please visit: www.kingsburyuk.com