Walter will be introducing two new machines at the forthcoming GrindTec exhibition (18-21 March 2020, Germany) and while full details of the new duo will not be released until the exhibition doors open, it has been announced that one of the new arrivals will be the twin-spindle option for the Helitronic Power 400 tool grinder and for the Helitronic Power Diamond 400 ‘two-in-one’ tool eroding and grinding machine.

The twin-spindle option machines offer 24 kW and are able to accommodate tools up to 520 mm long and up to 380 mm diameter.

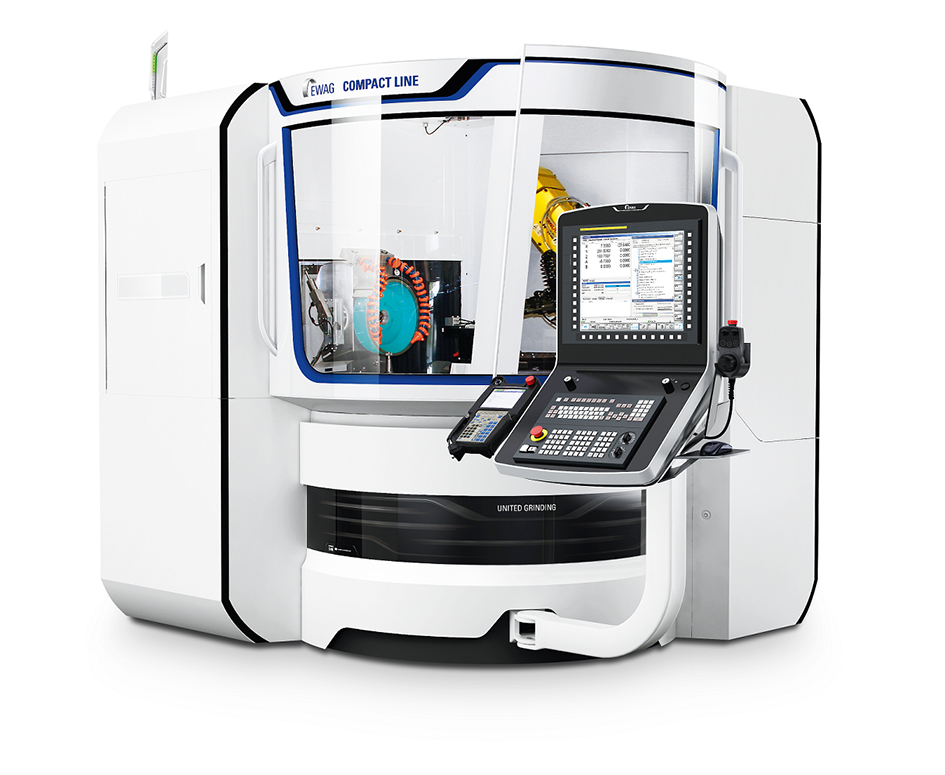

In addition to releasing a number of other tool production and measurement innovations as part of the United Grinding Group display (Stand 2055, Hall 2 in Messe Augsburg), Walter Ewag UK says Walter will also show the Helicheck Plus tool measuring machine with integrated robot laser marking (after cleaning), while Ewag will have the Laser Line Ultra, Compact Line and Profile Line insert production machines on show.

Laser marking on the Walter Helicheck Plus

While the Ewag Laser Line Ultra represents state-of-the-art, ultra-short pulse laser machining of all cutting materials, and accommodates inserts up to 200 mm diameter and up to 250 mm long – and the Profile Line is targeted at the production of complex insert geometries, including interchangeable cutting inserts and rotationally symmetrical drilling and milling inserts of HSS, carbide, cermet and ceramic – the six-axis Compact Line is designed for grinding (including peripheral grinding) inserts of tungsten carbide, cermet, ceramic, PCBN and PCD.

The machine’s traverses in the X, Y and Z axes are 450 mm, 180 mm and 150 mm, respectively, while axis resolution is 0.0001 mm. The 5.5 kW grinding spindle produces 7,000 revs/min.

A ‘three-in-one’ dressing unit ensures grinding wheel concentricity and high process reproducibility, plus it offers wheel dressing, regeneration and ‘crushing’ in a single package. Machine usability and effectiveness is also guaranteed by the integrated ProGrind software, and the Fanuc control system enables all grinding routines to be programmed quickly and easily via its user-friendly touch-screen panel.

Applying protective chamfers on inserts’ main cutting edges is ensured by the machine’s optimised kinematics as well as by the new C axis. Machine downtime is minimised by the machine’s short travel distances and by the integrated six-axis Fanuc robot that offers agile handling and a high degree of flexibility for loading complex inserts.