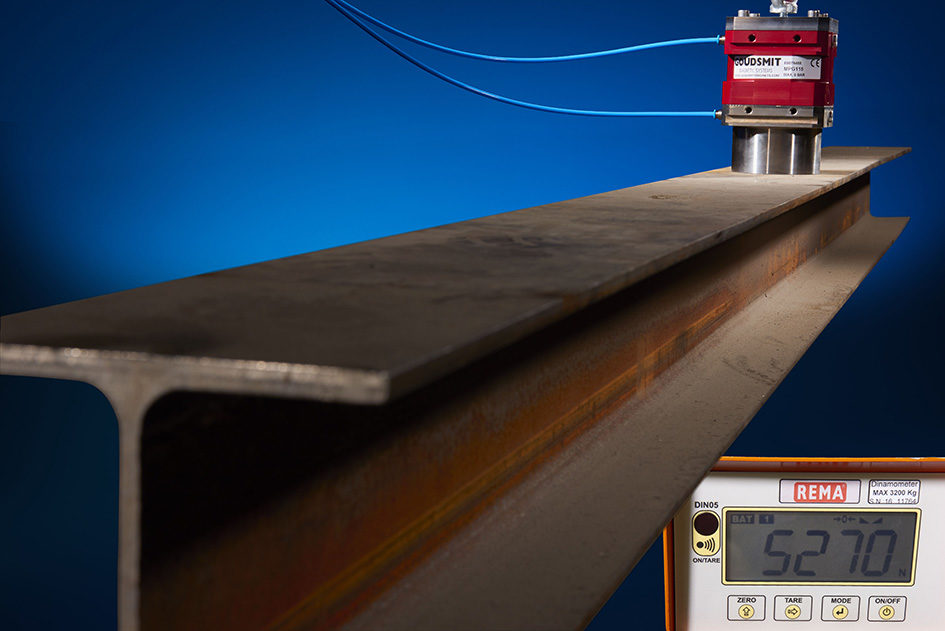

At the Euroblech in Hanover (Stand 12B153) Goudsmit Magnetics presents a recently developed compact, strong magnetic gripper, known as the Powergripper. This magnet handles and holds heavy ferromagnetic parts such as rolled profiles, bar material as well as solid steel products in the shape of grilles, plates and milled parts, brake discs and steel wheels. The magnetic gripper, mounted on a robot or XYZ manipulator, picks up over 100 kg. effortlessly. The gripper, fitted with neodymium magnets, is pneumatically switchable, yet it is permanently magnetic. This provides extra safety, because the magnet retains the heavy load even in the event of a loss of compressed air. This requires no backup system of any kind, which means low investment and maintenance costs and a simple controller. To give an idea of the ratio of compactness to magnetic force: a #115 mm Powergripper weighs 9.5 kg, safely lifts a load of about 175 kg and has a holding force of 527 kg.

FEM ANALYSES

In comparison with the standard magnetic gripper, which has the same application but is intended for thin-walled sheet material, a power gripper with the same diameter is 3.5 times stronger. To achieve this, Goudsmit has developed a closed magnetic circuit with neodymium magnets that makes direct contact with the handled product via steel legs. This pole configuration was calculated with FEM analyses and optimized to the extent that the circuit is less susceptible to widening of the air gap between the poles and the gripped object. This ensures the optimum holding force and even makes it possible to handle rusty products safely. The magnetic gripper is made with a special bearing-supported suction cup assembly that tests have shown to have a service life of at least one million strokes.

This Powergripper is less suitable for use on thin-walled products. At wall thicknesses below 10 mm the lifting force is relatively lower, so the normal gripper is more suitable. Tests show the relative lifting forces of power versus normal grippers, which gripper is best suited for which product and what the safe holding force is.

APPLICATIONS

In a robot application the Powergripper serves to pick up or hold solid, heavy steel parts, such as cast parts, hot rolled profiles, solid bar material and thick-walled welded constructions. These magnetic grippers are also used for picking up steel workpieces for processing in saws and machine tools as well as welding and grinding processes. The on/off position is detectable by means of market-standard sensors that can be mounted in the slotted holes specially provided for this purpose. It is also possible to join two or three power grippers together with special connection strips for heavy-lift applications, such as in shipyards, to lift hull sections that weigh tonnes. The magnets can be switched on and off via simple pneumatic control using a 5/2 or 5/3 valve. What makes this magnet system so special is that it is very powerful when switched on yet has hardly any residual magnetism when switched off; the magnet is truly off. The magnet is maintenance free, has a long life and is available in various sizes.